About

We are a professional passionate team.

DESIGN

Design is the highest priority of bicycle framesets. Correct geometry will make riding more comfortable. Better designed disc brake will avoid conflict between rack and disc caliper. So we spent our majority of time on design and testing before massive production. We must ensure our crafts are perfect at details.

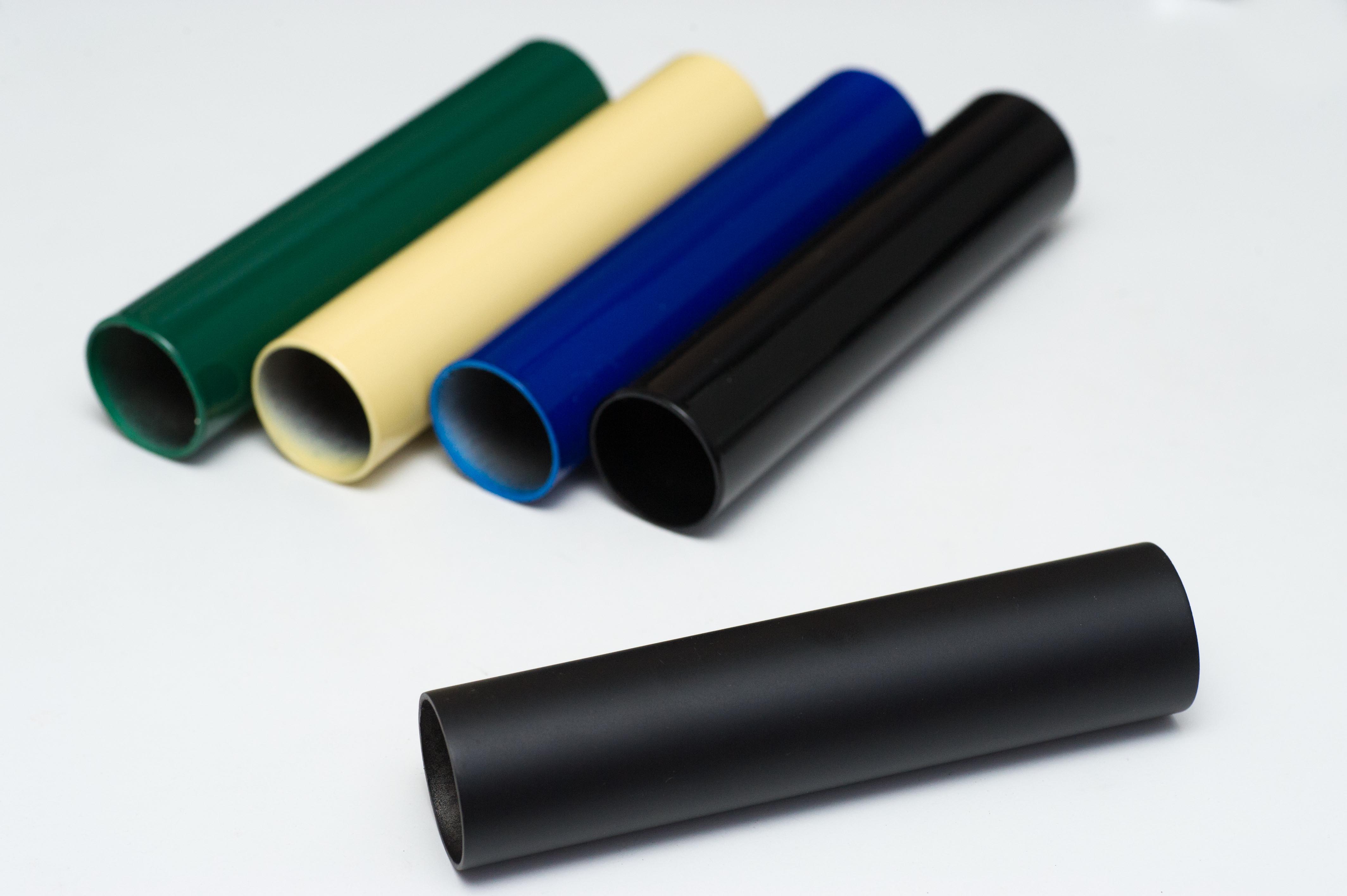

MATERIAL

Steel is real. We believe premium quality 4130 Cr-Mo tubes will last long and with comfortable experience. So far our bikes are all built with steel. With technology develop, now we even use butter procedure, heat treatment, ED coating on high-end product line, which makes tubes stronger, lighter, and more durable.

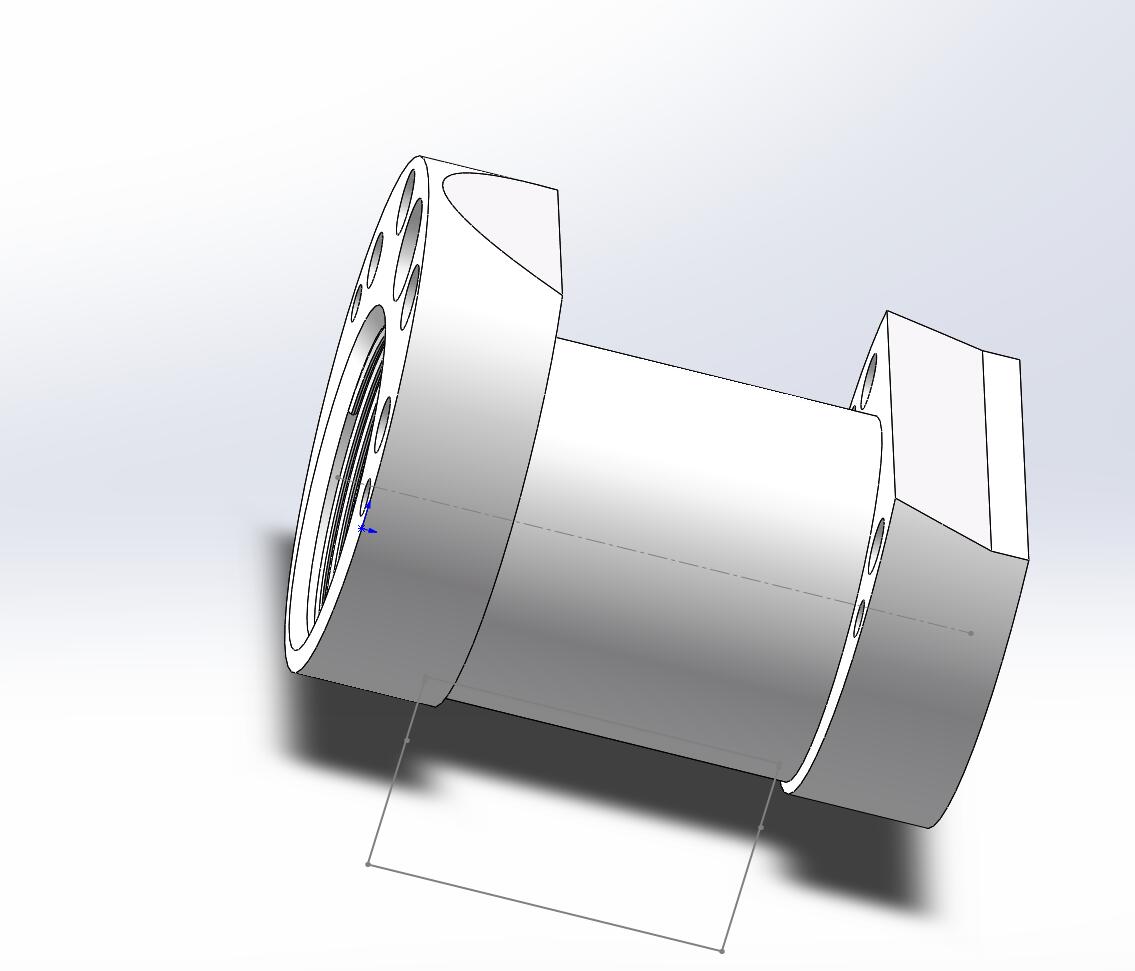

BUILD

From tube pre-processing to welding, from ED coating to alignment, we treat your bicycle frames as our own. All dropouts are in-house built to ensure highest quality. Paint job is handover to our partner workshop to ensure environment friendly.

RIDE

The best product is never proved in laboratory. Either ourselves or our sponsor riders will test our new crafts in the real world. Thus we learn the real need of our customers and build our bicycles better in details.

VALUE

Due to unfair trade, and some other reasons, some touring bicycles are expensive, although most of them are made in China or Taiwan. After investigation, we found there’s no mystery to build premium quality bicycles and parts, while still within affordable price. Then we started to build them for our own from year 2013 and later for those people love cycling too. We hope more people will enjoy riding and afford less.

TEAM

Blacksnow is yet still a growing brand. However, each person has full spirit of cycling and indispensable at his/her professional area. We trust our passion will drive to make things perfect, and we believe in-house build will ensure the better quality even though at entrance price level.